|

|

Screen Exchanger(Model: PSC120A)

It's designed with advanced stable multi-mesh technology enable non-stop exchange of mesh.

Flow channel properly designed to avoid over-heating polymer. Automatic control system is reliable and easy for operation.

Technical data Motor: 2.2KW

Heating power: 3.2KWX2

Oil hydraulic driven Fore and post pressure sensor included |

Characteristics

Non-stop design

Stable temperature control

Low noise

Stable pressure control No leakage of polymer |

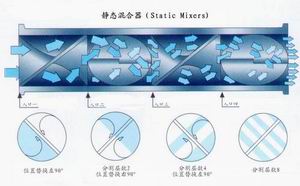

Static Mixing Device

Made of tubes with produced internal modules,high heat transfer coefficient,simple process,compact construction,low energy consumption,low investment,flexible operation,no maintenance and good mixed performance.

|